Great Wall Hover. Manual - part 60

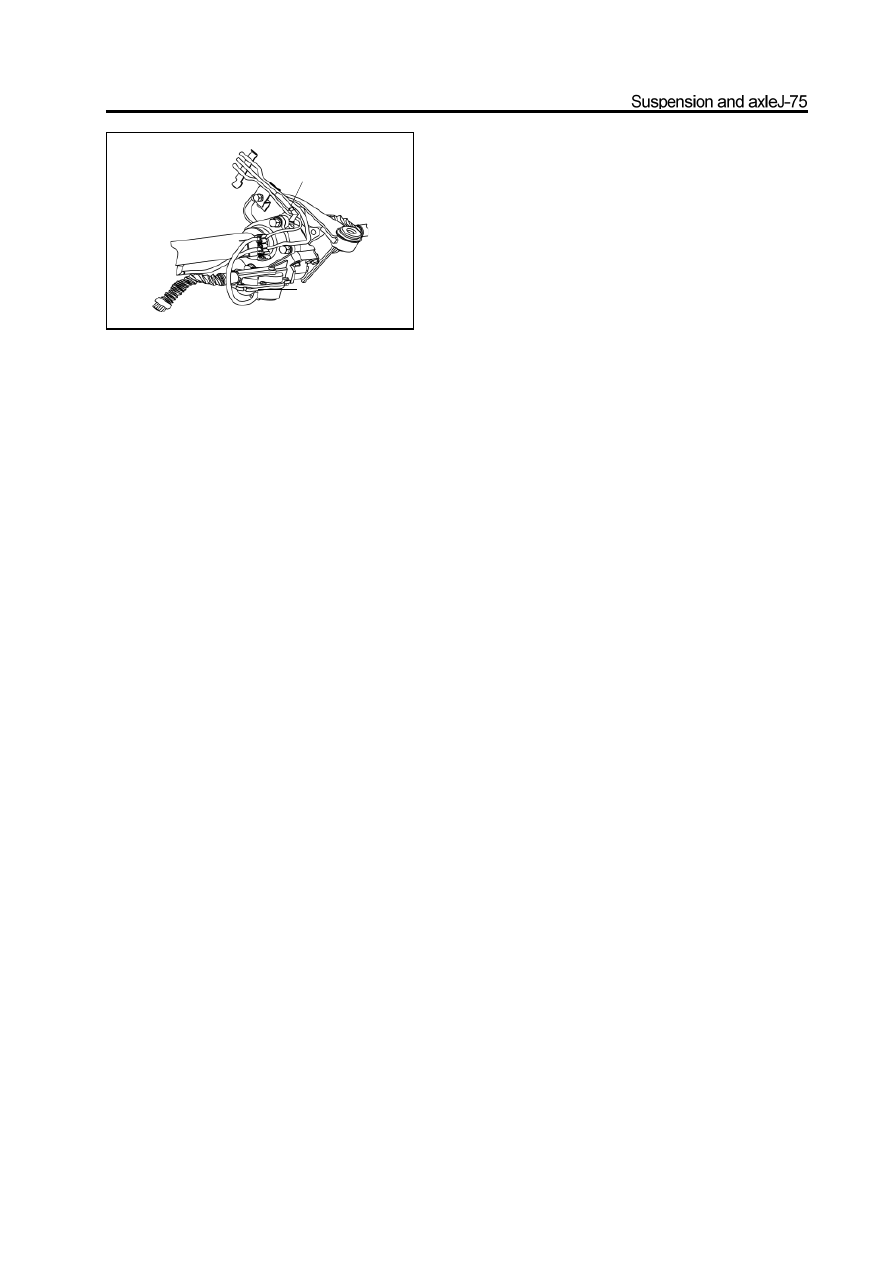

20. Connect the vent tube on the electric clutch

housing to the front axle vent tube connector

assembly.

21. Connect the electric clutch vent tube to the

front axle vent tube connector assembly.

connect the place

connect the place