содержание .. 331 332 333 334 335 ..

Geely Emgrand X7. Manual part - 334

A. rotated ignition switch to OFF position.

B. Disconnect the harness connector J-4 of the

electromagnetic valve.

C. Measure the resistance between Terminal 6 of the

electromagnetic valve harness connector J-4 and

Terminal No.1 of the automatic control module

J-1.

D. Measure the resistance between Terminal No.1 of

the electromagnetic valve harness connector J-4

and Terminal 7 of the automatic control module

J-1.

E. Turn the ignition switch to the ON position.

F. Measure voltage of electromagnetic valve

harness connector J-4No.6 terminal and reliable

grounding

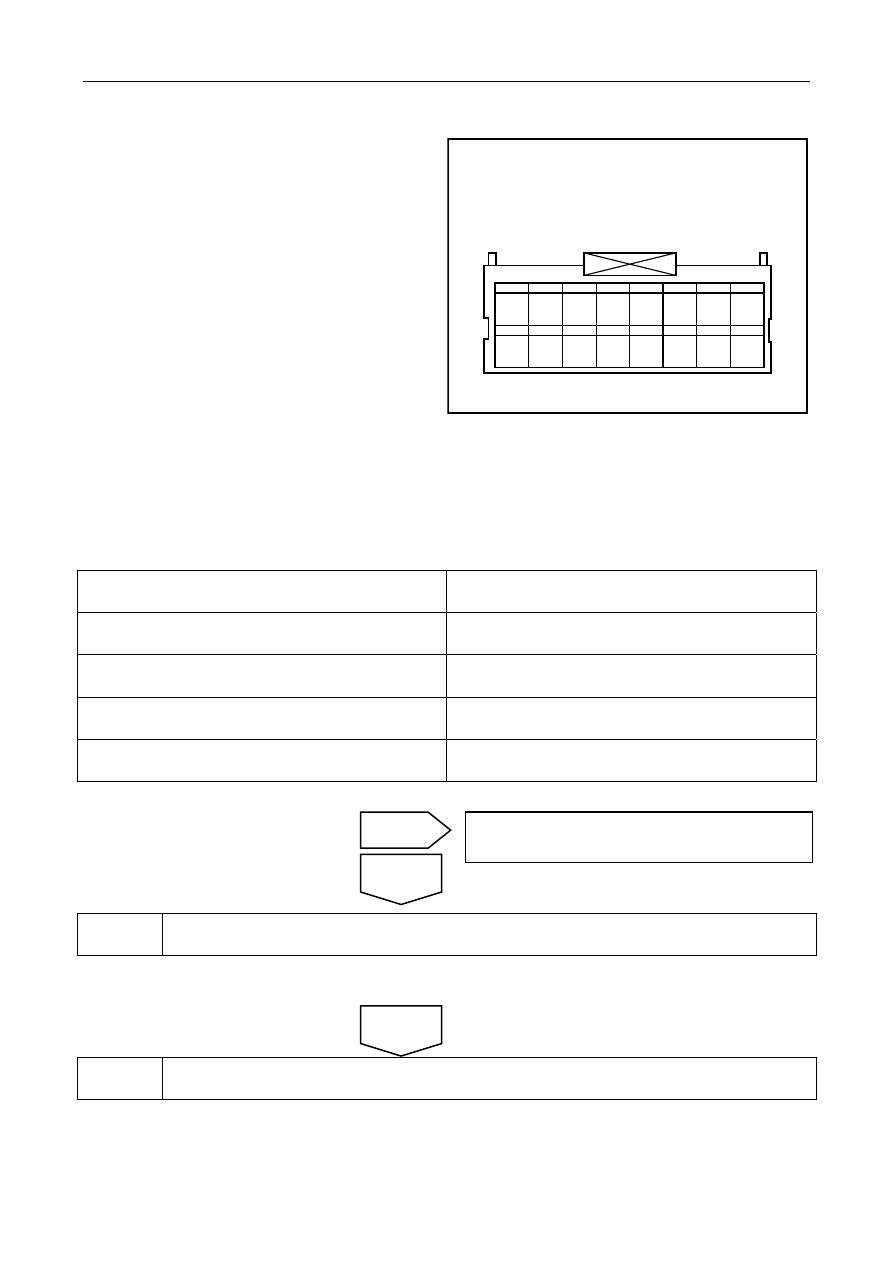

自动变速器控制模块线束连接器

J-1

1

9

2

10

3

11

4

12

5

13

6

14

7

15

8

16

SL03-0034c

G. Measure the resistance between Terminal No.1 of the electromagnetic valve harness connector J-4 and secure

ground wire.

Results

Test Items

Standard Value

J-4 (6) — J-1(1)

Less than 3 Ω

J-4 (1) — J-1(7)

Less than 3 Ω

J-4 (6) — Reliable grounding voltage value

0 V

J-4 (1) — Reliable grounding resistance value

Less than 3 Ω

Does it conform to the standard value?

4 ReplaceTCU

Refer to3.5.7.8 replace automatic transmission control module

5

Go to automatic transmission fresh process.

Refer to3.5.7.4 Automatic transmission refresh process

No

Yes

Circuit malfunction, repair circuit.

Next

Auto-transmissioncontrol module harness connectorJ-1

1335