содержание .. 274 275 276 277 278 ..

Geely Emgrand X7. Manual part - 277

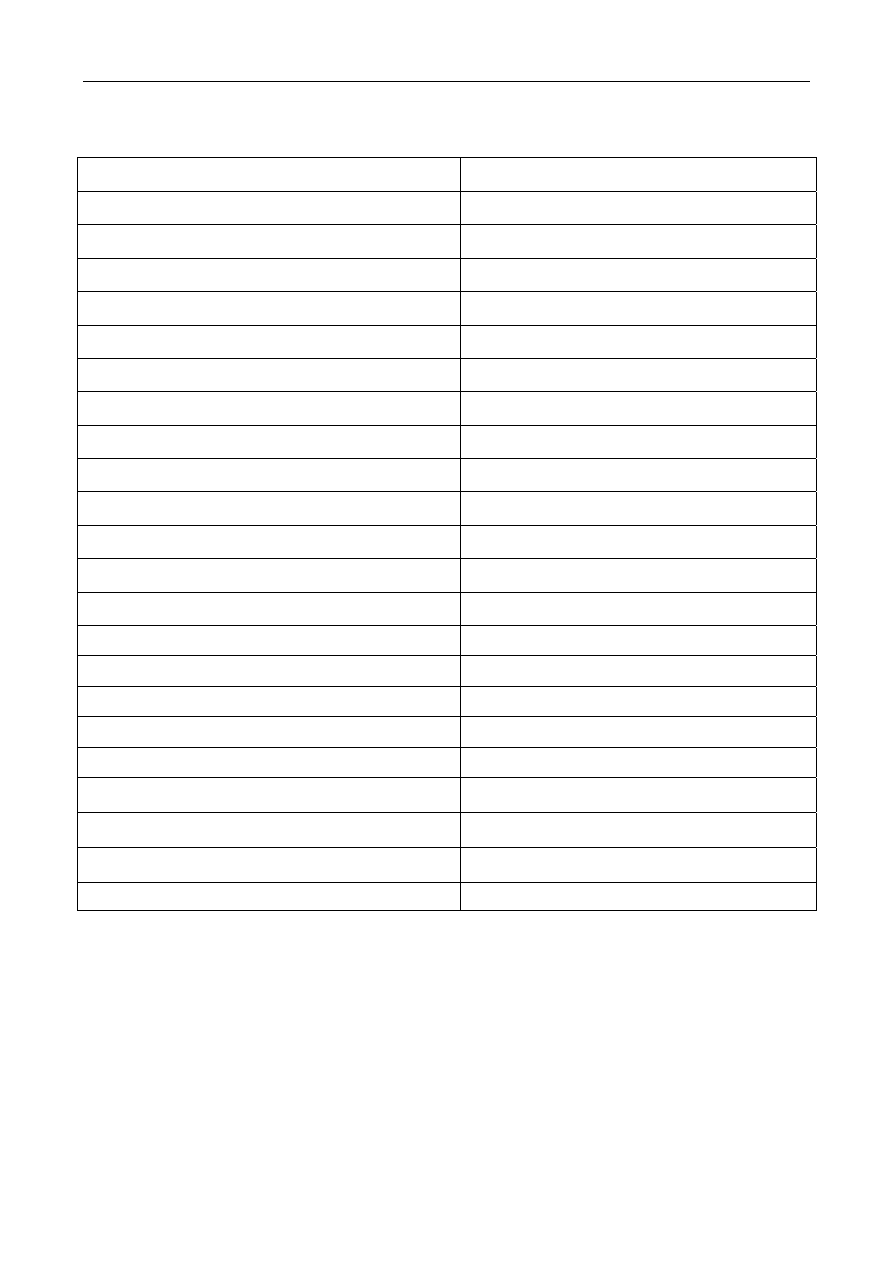

3.3.1.2 Manual transmission specifications

Transmission specifications

Applications Specification

Gear ratio

1st speed

3.583

2nd speed

1.947

3rd speed

1.379

4th speed

1.03

5th speed

0.82

Reverse gear

3.363

Main reduction ratio

4.058

Maximum speed

200

0~100km/h Maximum gradeability

15.2

Maximum gradeability

40

Gear oil capacity

2.2L

Lubrication oil type or model

75W/90 GL-4

Axial clearance for input shaft front bearing Mm

-0.01~0.21

Axial clearance for input shaft rear bearing mm

-0.01~0.12

Axial clearance for input shaft 5th speed gear mm

-0.01~0.09

Axial clearance of output shaft front bearing mm

-0.01~0.12

Axial clearance of output shaft rear bearing mm

-0.01~0.09

3st speed axial clearance of output shaft mm

-0.01~0.09

Differential housing pinion gap mm

0.025~0.150

Differential housing tightness mm

0.05~0.11

Clearance between synchronizer back and gear mm

Limit value 0.05

1107