содержание .. 144 145 146 147 148 ..

Geely Emgrand X7. Manual part - 147

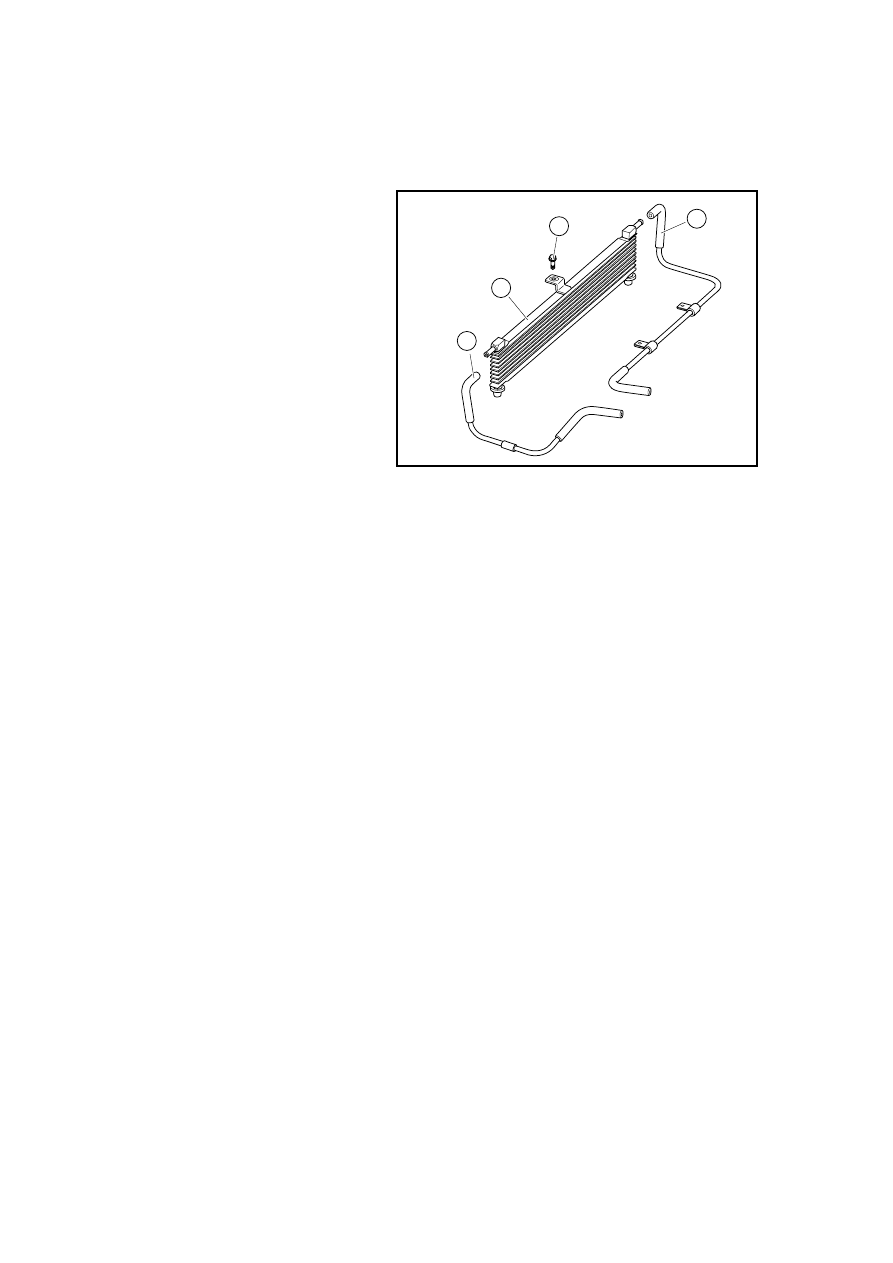

2.8.8.6 oil cooler replacement (with DSIAuto-transmission )

Dismantlement Procedure

1. Disconnect the battery negative

electrode cable.

Refer

to

2.12.6.1 Battery Disconnection.

2. For drainage of automatic

transmission oil, refer to 3.4.7.3

Replacement procedures of

automatic transmission oil.

3. Dismantle oil cooler oil inlet

hose 1 .

4. Dismantle oil hose 2 of oil

cooler.

3. Dismantle oil cooler assembly

fixing bolt 3 .

4. Dismantle oil cooler assembly 4.

Installation Procedure:

1. Install oil cooler and tighten

fixing bolt.

2. Connect oil inlet and outlet hose

of oil cooler.

3. Filled Auto-transmission oil .

2

1

3

4

NL02-2002c

587