Ford Fiesta (1989-1995). Instruction - part 31

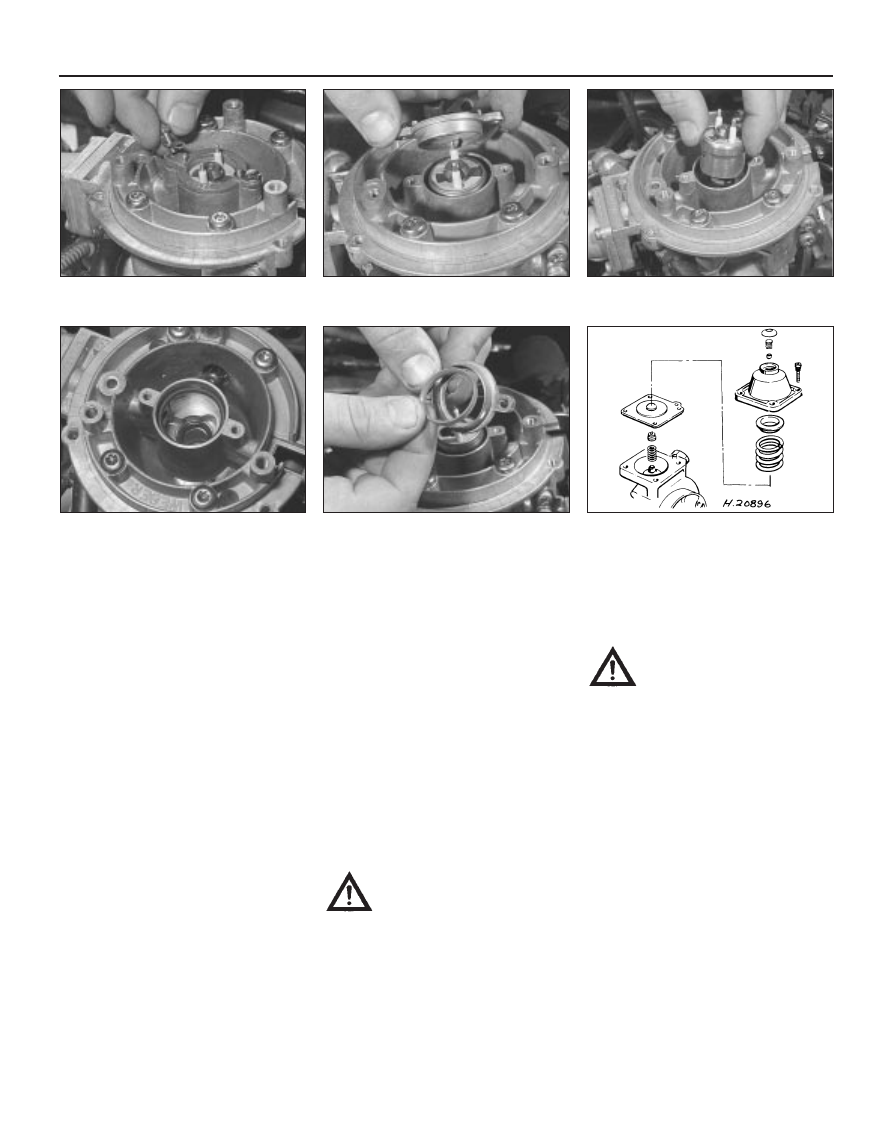

5 Bend over the locking tabs retaining the

injector screws, then undo and remove the

screws. Withdraw the injector retaining collar,

then carefully withdraw the injector from the

CFi unit (noting its orientation) followed by its

seals. Withdraw the seal from the retaining

collar (see illustrations).

6 Refit in the reverse order of removal.

Always use new seals in the CFi unit and the

retaining collar, and lightly lubricate them with

clean engine oil prior to assembly. Take care

not to damage the seals as they are fitted and

as the injector is fitted, check that the location

peg engages correctly.

Fuel pressure regulator

7 Refer to paragraphs 14 to 22 in this Section

and remove the CFi unit from the vehicle.

8 Unscrew and remove the four regulator

retaining screws, and remove the regulator

(see illustration). As they are removed, note

the fitting positions and the orientation of the

components. Do not (unless absolutely

necessary) attempt to prise out the plug or

adjust the screw in the centre of the housing

(if no plug is fitted), as this will alter the system

pressure.

9 Examine the components, and renew any

that are defective or suspect.

10 To refit, position the regulator on its side,

then insert the small spring, the valve,

diaphragm (ensuring that it seats correctly),

large spring, cup and then the regulator cover.

Insert and tighten the retaining screws, but

take care not overtighten them, or the cover

will be distorted.

11 Carefully place the ball into position on

the spring cup, and ensure that it seats

correctly.

12 If removed, fit the central Allen type

adjuster screw, hand-tighten it and then

unscrew it (from the hand-tight position) three

full turns to make a provisional adjustment.

13 Refit the CFi unit in accordance with

paragraphs 23 to 25 in this Section, but note

that further checks for fuel leaks must be

made with the engine running. The fuel

system pressure must be checked by a Ford

dealer or other suitable specialist at the

earliest opportunity.

CFi unit

14 Relieve the residual pressure in the fuel

system (see Section 2), and equalise tank

pressure by removing the fuel filler cap.

Warning: This procedure will

merely relieve the increased

pressure necessary for the

engine to run - remember that

fuel will still be present in the system

components, and take precautions

accordingly before disconnecting any of

them.

15 Disconnect the battery negative (earth)

lead (refer to Chapter 5A, Section 1).

16 Refer to Section 4 and remove the air

cleaner.

17 Position a suitable drain tray under the

coolant hose connections to the CFi unit.

Ensure that the cooling system is not

pressurised (see Chapter 1), then detach the

hoses from the unit. Plug or clamp the hoses

to prevent further coolant spillage whilst the

hoses are detached.

Warning: DO NOT attempt to

remove the expansion tank filler

cap, or to disturb any part of the

cooling system, while it or the

engine is hot, as there is a very great risk

of scalding. If the expansion tank filler cap

must be removed before the engine and

radiator have fully cooled down (even

though this is not recommended) the

pressure in the cooling system must first

be released. Cover the cap with a thick

layer of cloth, to avoid scalding, and slowly

unscrew the filler cap until a hissing sound

can be heard. When the hissing has

stopped, showing that pressure is

released, slowly unscrew the filler cap

further until it can be removed; if more

hissing sounds are heard, wait until they

have stopped before unscrewing the cap

completely. At all times, keep well away

from the filler opening.

18 Disconnect the fuel return pipe from the

CFi unit.

19 Refer to Section 5 and disconnect the

accelerator cable from the CFi unit.

20 Disconnect the inlet air temperature

sensor, throttle plate control motor and

throttle position sensor wiring multi-plug

connectors.

4B•6 Fuel system - central fuel injection engines

14.8 Exploded view of the fuel pressure

regulator assembly

14.5e Withdrawing the seal from the

injector retaining collar

14.5d Injector seals in the CFi unit

14.5c Withdrawing the injector from the

CFi unit

14.5b Removing the injector retaining

collar

14.5a Removing an injector retaining

collar securing bolt and its locktab

1595Ford Fiesta Remake