Dodge Nitro. Manual - part 378

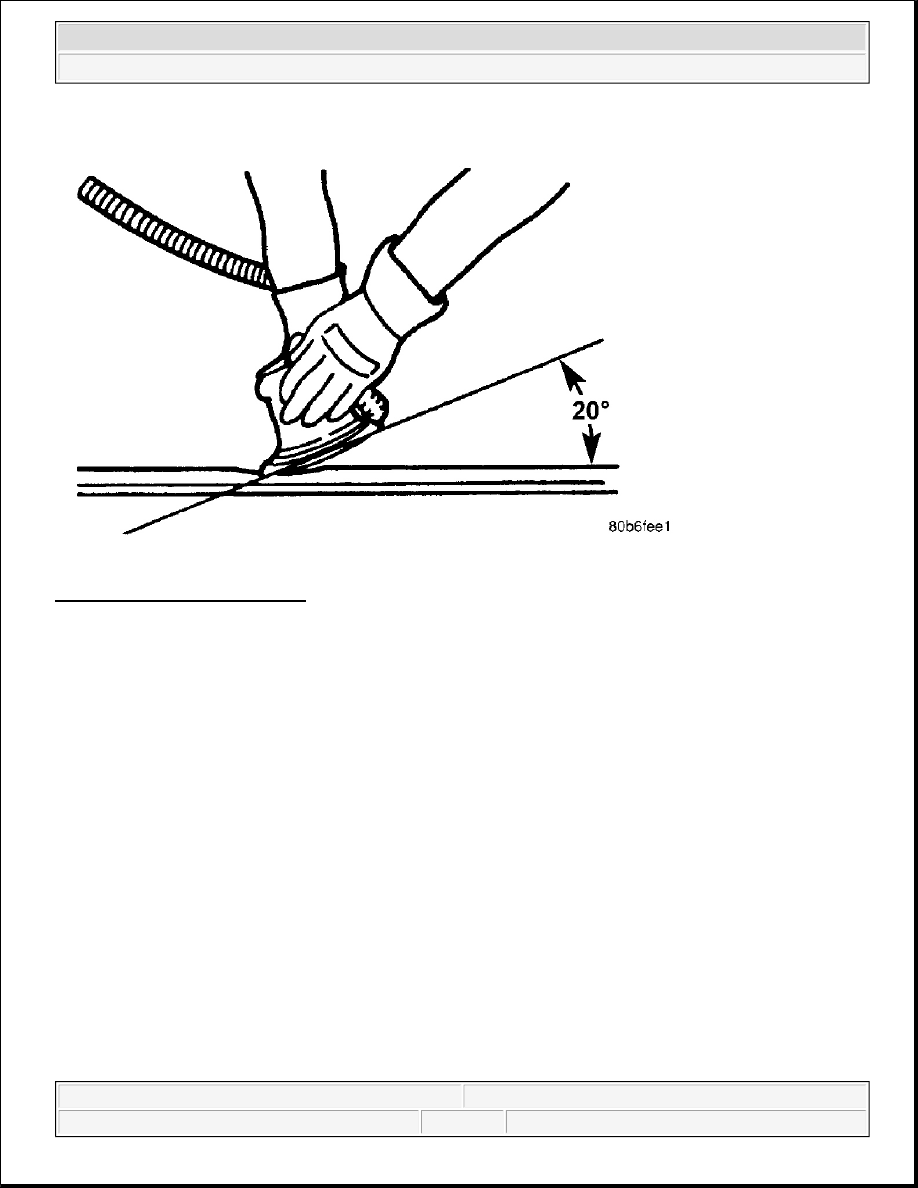

Fig. 4: Beveling 20 Degree Angle

Courtesy of CHRYSLER LLC

When repairing plastic, the damaged area is first "V'd" out, or beveled. Large bonding areas are desirable when

repairing plastic because small repairs are less likely to hold permanently. Beveling the area around a crack at a

20° angle will increase the bonding surface for a repair. It is recommended that sharp edges be avoided because

the joint may show through after the panel is refinished.

2007 Dodge Nitro R/T

2007 ACCESSORIES AND EQUIPMENT Body - Nitro