Dodge Nitro. Manual - part 47

LUBRICATION

DESCRIPTION

LUBRICATION

The lubrication system is a full flow filtration pressure feed type.

OPERATION

LUBRICATION

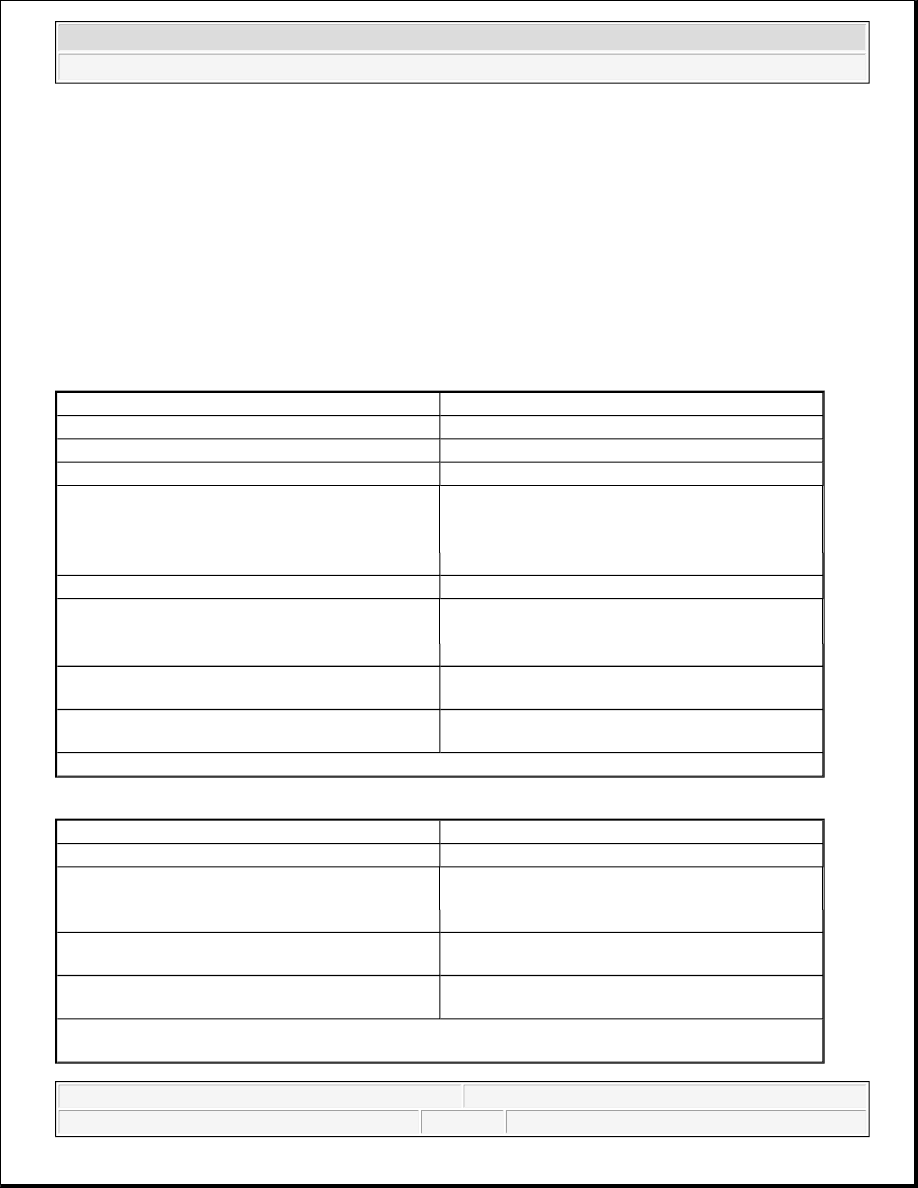

Engine Lubrication Flow Chart - Block: Table 1

Engine Lubrication Flow Chart - Cylinder Heads: Table 2

FROM

TO

Oil Pickup Tube

Oil Pump

Oil Pump

Oil Filter

Oil Filter

Block Main Oil Gallery

Block Main Oil Gallery

1. Crankshaft Main Journal

-

2. Left Cylinder Head*

-

3. Right Cylinder Head*

-

4. Counterbalance Shaft Rear Journal

Crankshaft Main Journals

Crankshaft Rod Journals

Crankshaft Number One Main Journal

1. Front Timing Chain Idler Shaft

-

2. Counterbalance Shaft - Front Journal

-

3. Both Secondary Chain Tensioners

Left Cylinder Head

Refer to Engine Lubrication Flow Chart - Cylinder

Heads: Table 2

Right Cylinder Head

Refer to Engine Lubrication Flow Chart - Cylinder

Heads: Table 2

* The cylinder head gaskets have an oil restrictor to control oil flow to the cylinder heads

FROM

TO

Cylinder Head Oil Port (in bolt hole)

Diagonal Cross Drilling to Main Oil Gallery

Main Oil Gallery (drilled through head from rear to

front)

1. Base of Camshaft Towers

-

2. Lash Adjuster Towers

Base of Camshaft Towers

Vertical Drilling Through Tower to Camshaft

Bearings**

Lash Adjuster Towers

Diagonal Drillings to Hydraulic Lash Adjuster

Pockets

** The number three camshaft bearing journal feeds oil into the hollow camshaft tubes. Oil is routed to

the intake lobes, which have oil passages drilled into them to lubricate the rocker arms.

2007 Dodge Nitro R/T

2007 ENGINE 3.7L - Service Information - Nitro