DAF LF45, LF55 Series. Manual - part 264

©

200508

4-3

Removal and installation

ALLISON MD 3060 AUTOMATIC GEARBOX

ΛΦ45/55 series

3

8

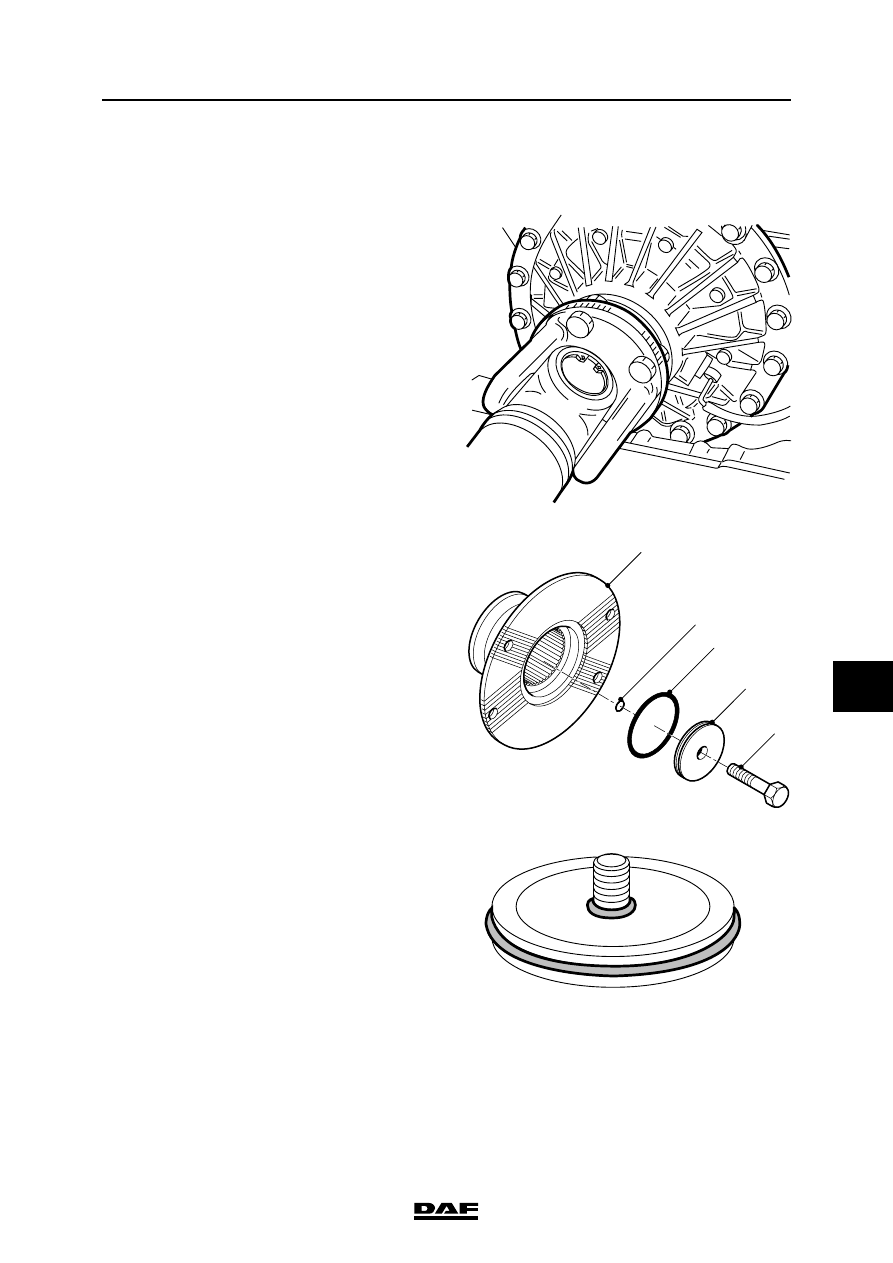

4.2 REMOVING AND INSTALLING OUTPUT SHAFT OIL SEAL

Removing output shaft oil seal

1.

Remove the prop shaft and secure it so that

it does not interfere with further operations.

2.

Unscrew the attachment bolt (5) of the flange

without removing it from the locking plate.

3.

Remove the bolt and locking plate from the

flange.

Pay attention to the sealing rings on the outer

circumference and on the inside of the

locking plate.

W 3 03 061

V300529

1

2

3

5

4

V300559