Chery Tiggo 5 (T21). Manual - part 114

07–

42

07

Flywheel

Removal

1. Turn off all the electrical equipment and ignition switch.

2. Disconnect the negative battery cable.

3. Remove the transmission assembly (

for CVT model).

4. Remove the clutch assembly (

).

5. Remove the flywheel.

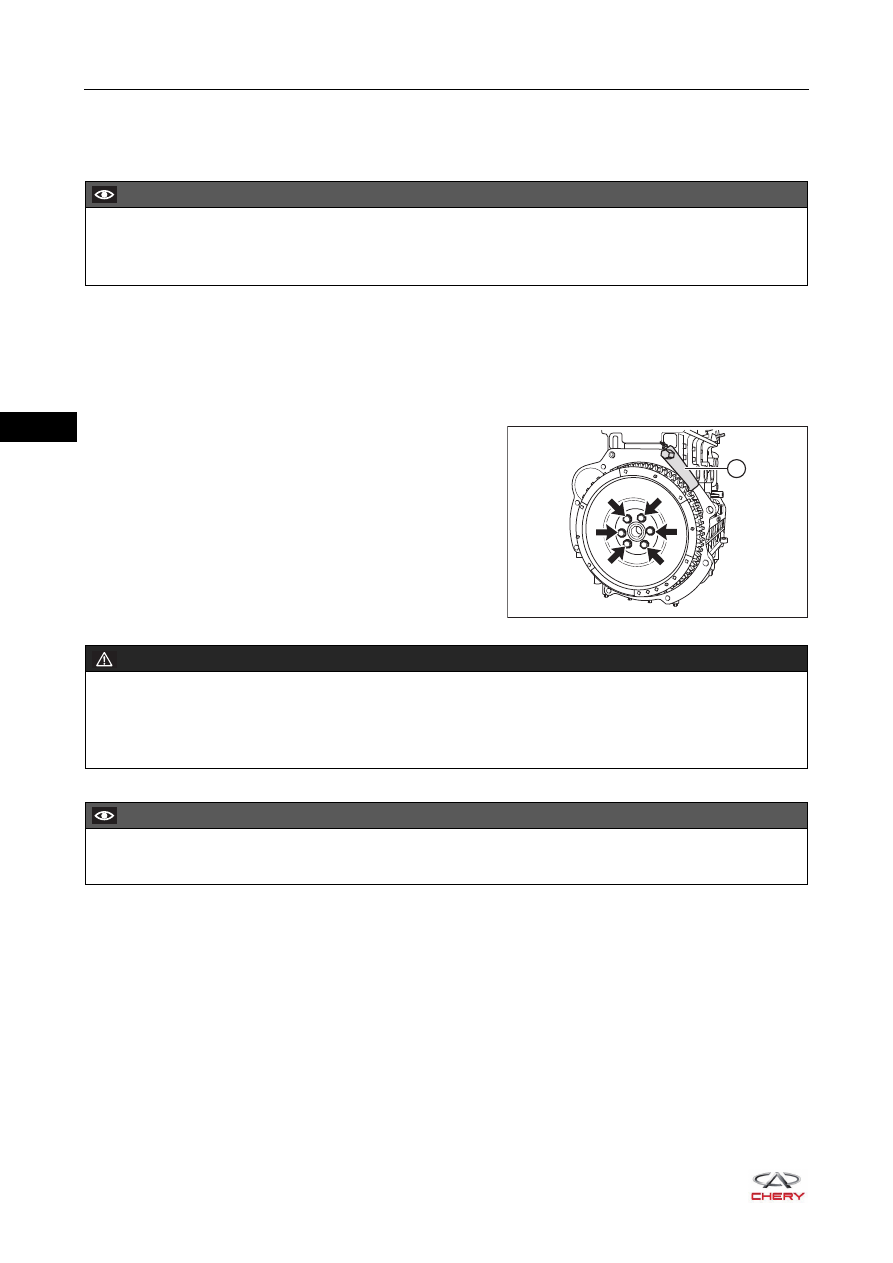

a. As shown in the illustration, install the flywheel holding

tool (1) to hold the flywheel securely.

b. Remove 6 fixing bolts (arrow) from flywheel, and

remove the flywheel.

(Tightening torque: 1st step: tighten to 35 ± 5 N·m;

2nd step: retighten by 45° ± 5°)

Inspection

1. Check if crankshaft position signal gear is distorted or deformed. If damaged, replace the flywheel. Clean

the signal gear before installation.

2. Check if starter drive gear ring is worn. If excessively worn, replace the flywheel.

3. Check contact surface of clutch lining. If the contact surface is damaged or excessively worn, replace the

flywheel with a new one.

CAUTION

Be sure to wear necessary safety equipment to prevent accidents when repairing.

Try to prevent body paint surface from being scratched during removal and installation.

1

RT21070290

WARNING

Pay special attention to safety during operation, do not remove all flywheel fixing bolts without any

auxiliary measures.

If necessary, other operators will be required to assist.

CAUTION

Flywheel fixing bolts must be disposed after removal. Never reuse them.