Chery A11. Manual - part 176

Maintenance Manual for Chery · Windcloud

M7.9.7 EFI System

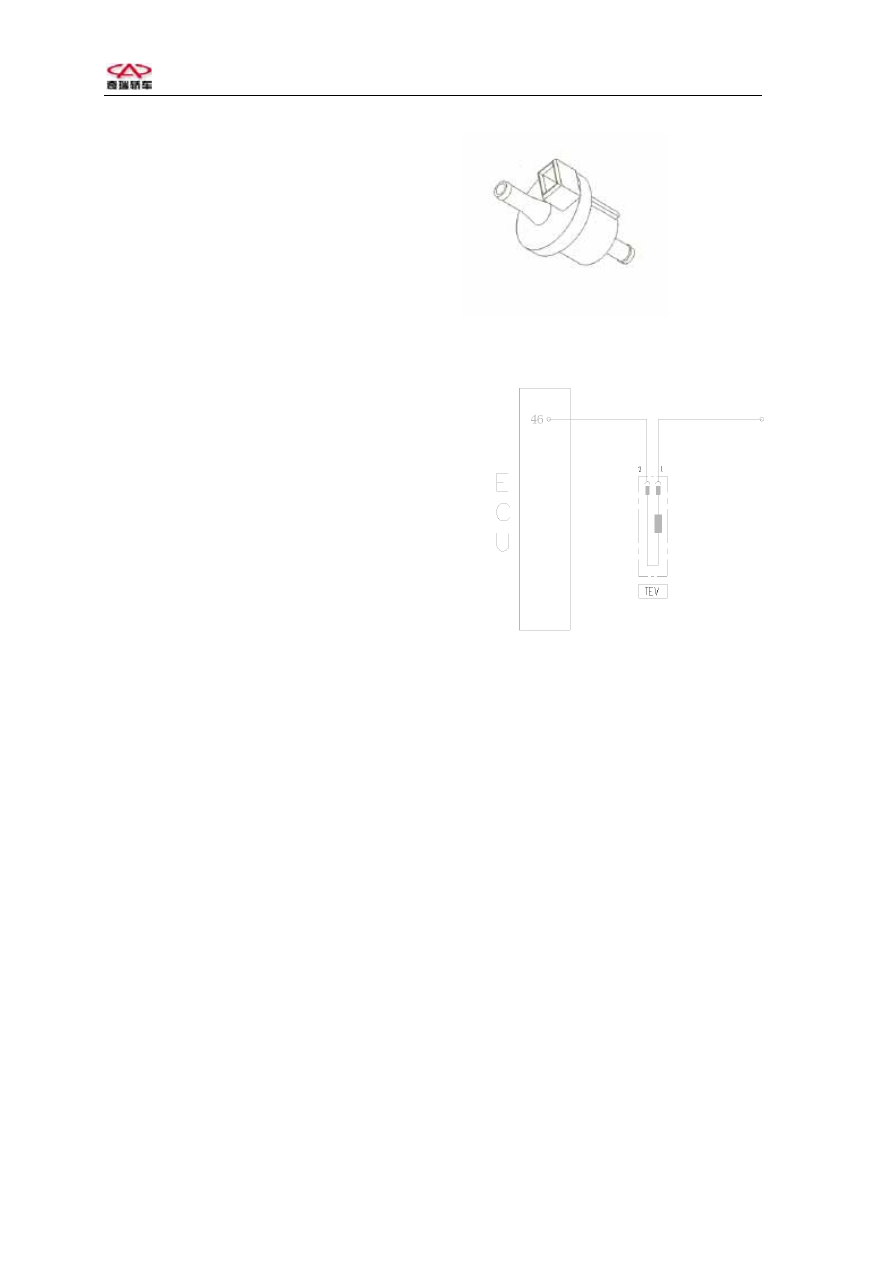

11. Carbon Canister Control Valve

Purpose: to be used for the control of purge

flow rate of carbon canister. Carbon canister

control valve is controlled by ECU in

accordance with engine load via the duration

and frequency of electric impulse (i.e. duty

ratio). Excessive accumulation of gasoline

vapor in charcoal canister will lead to

gasoline leakage and pollution, therefore,

the function of carbon canister

electromagnetic valve is to open the said

valve as appropriate so as to transfer

excessive gasoline vapor into air intake pipe

for combustion.

Composition and principle: carbon

canister control valve consists of solenoid,

armature and valve, etc. There is a filter

screen on inlet. And the airflow rate passing

through carbon canister control valve is

related to duty ratio of electric impulse

outputed by ECU to the said valve on one

hand, while related to pressure difference

between its inlet/outlet on the other hand. In

case there is no electric impulse, carbon

canister control valve will shut down. ECU

controls the said valve’s current-on time and

indirectly controls the rate of purge flow

according to signals provided by sensors of

engine.

Failure diagnosis: ECU functions failure

diagnosis on driver stage of carbon canister

control valve instead of the said valve. In

case short circuit, overload, short circuit to

ground or open circuit occurs on driver stage

of carbon canister control valve to

accumulator voltage, fuel rated closed-loop

control basic self-learning and idle speed air

requirement self-learning are shut down, and

the self-learning data are valid. If failure

occurs on the aforesaid valve, generally

engine shows instable idle speed or

excessive idle speed.

Carbon canister control valve

Main relay

Carbon canister

control valve

Circuit diagram of carbon canister control valve

TEV-2

Pins:

Pin 1 connecting with Pin 87 of output

terminal of main relay;

Pin 2 connecting with Pin 46 of ECU.

Troubleshooting: blockage or crack of

carbon canister causes the increase of air

intake.

12