Bobcat S150. Manual - part 2

S150 Bobcat Loader

Operation & Maintenance Manual

VI

SERIAL NUMBER LOCATIONS

Always use the serial number of the loader when

requesting service information or when ordering parts.

Early or later models (identification made by serial

number) may use different parts, or it may be necessary

to use a different procedure in doing a specific service

operation.

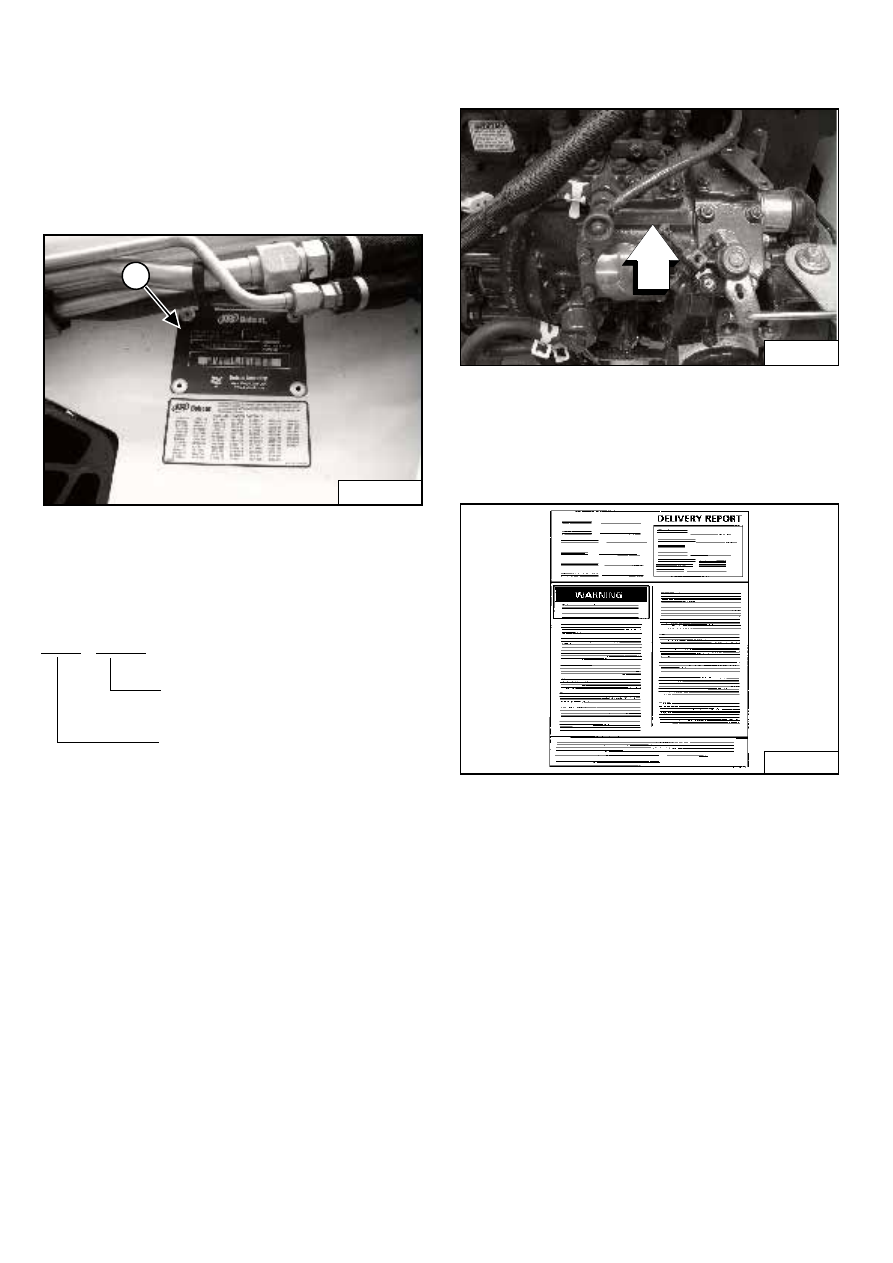

Figure 1

LOADER SERIAL NUMBER

The loader serial number plate is located on the outside

of the loader frame [Figure 1].

Explanation of loader Serial Number:

ENGINE SERIAL NUMBER

Figure 2

The engine serial number is located on the side of the

engine [Figure 2].

DELIVERY REPORT

Figure 3

The delivery report must be filled out by the dealer and

signed by the owner or operator when the Bobcat loader

is delivered. An explanation of the form must be given to

the owner. Make sure it is filled out completely [Figure 3].

1

P-45263

XXXX

XXXXX

Module 2. - Production

Sequence (Series)

Module 1. - Model / Engine

Combination

1. The four digit Model/Engine Combination Module

number identifies the model number and engine

combination.

2. The five digit Production Sequence Number identifies

the order which the loader is produced.

P-48387

B-16315