Loader Bobcat 853, 853H. Manual - part 62

FLYWHEEL

Removal And Installation

Remove the drive belt. (See Page 3–1.)

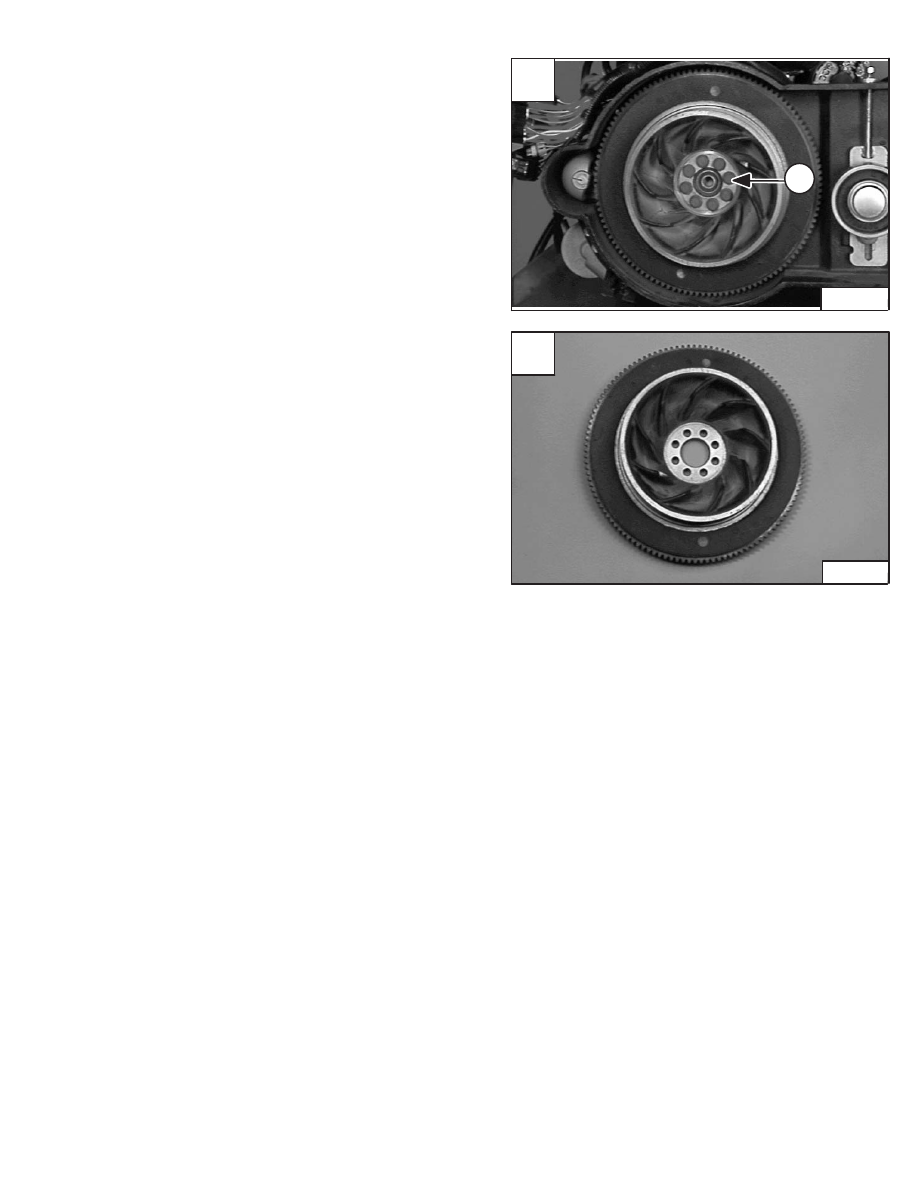

Remove the bolts (Item 1) [A] from the flywheel.

Installation: Put LOCTITE on the flywheel bolts. Tighten

the bolts to 83–90 ft.–lbs. (113–122 Nm) torque.

Remove the flywheel from the engine crankshaft [B].

Flywheel Ring Gear

The ring gear on the flywheel is an interference fit. Heat

the ring gear enough to expand it and hit it with a hammer

to remove it evenly.

Clean the outer surface of the flywheel to give it a smooth

fit.

Clean the new ring gear and heat it to a temperature of

450–500

°

F (232–260

°

C).

Fit the ring gear over the flywheel. Make sure the gear is

on the seat correctly.

NOTE: Early S/N Loader does not have cooling fins

in flywheel.

A

P–04928

1

853, 853H Loader

–7–37–

Service Manual

B

P–04939