Loader Bobcat 773. Manual - part 96

PISTON AND CONNECTING ROD

Removal And Installation

Remove the cylinder head. (See Page 7–47.)

Remove the top edge from the cylinder bore with a ridge

reamer.

Remove the oil pan.

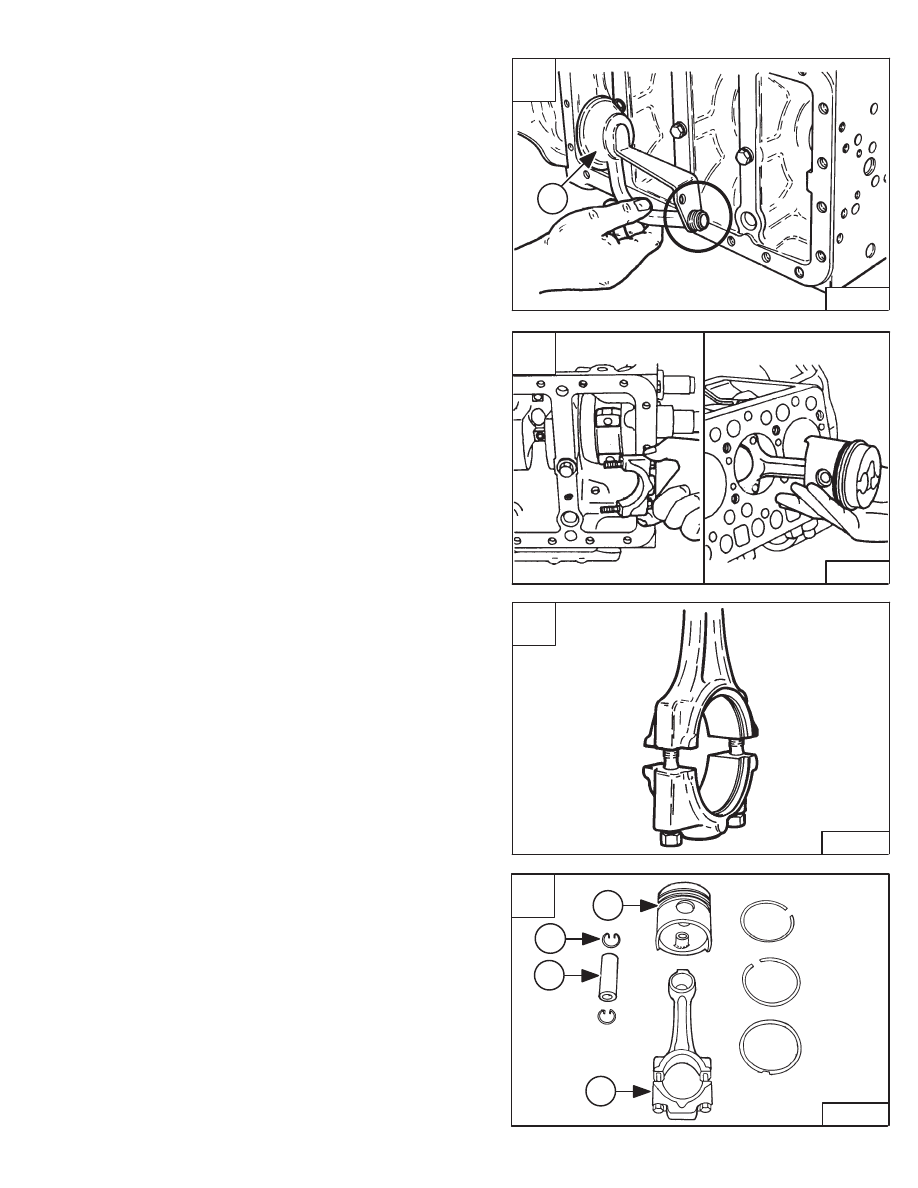

Remove the oil pump strainer (Item 1) [A].

Turn the flywheel and put a pair of connecting rods at

bottom dead center.

Remove the connecting rod bolts.

Installation: Tighten the connecting rod bolts to the

following torque.

W/O Flange Bolt

27–30 ft.–lbs. (37–41 Nm)

. . . . . . . . .

W/Flange Bolt

33–36 ft.–lbs. (45–49 Nm)

. . . . . . . . . . .

Remove the rod cap and bearing [B].

Use a hammer handle and push the piston/connecting

rod assembly out of the cylinder bore [B].

NOTE: Make sure the pistons are marked so they will

be returned to the same cylinder bore.

Installation: When inserting the piston into the cylinder,

face the mark on the connecting rod to the injection pump

[C].

Repeat the procedure to remove the other piston/

connecting rod assemblies from the engine block.

Remove the piston rings [D].

Remove the snap ring (Item 3) [D] and piston pin (Item 1)

[D].

Separate the piston (Item 2) [D] from the connecting rod

(Item 4) [D].

A

B–14344

1

C

A–02903

82.8

82.8

D

B–03621

1

3

2

4

773 BICS Loader

–7–63–

Service Manual

B

PI–10013