Porshe 911 (997). Manual - part 385

Cutting the side section

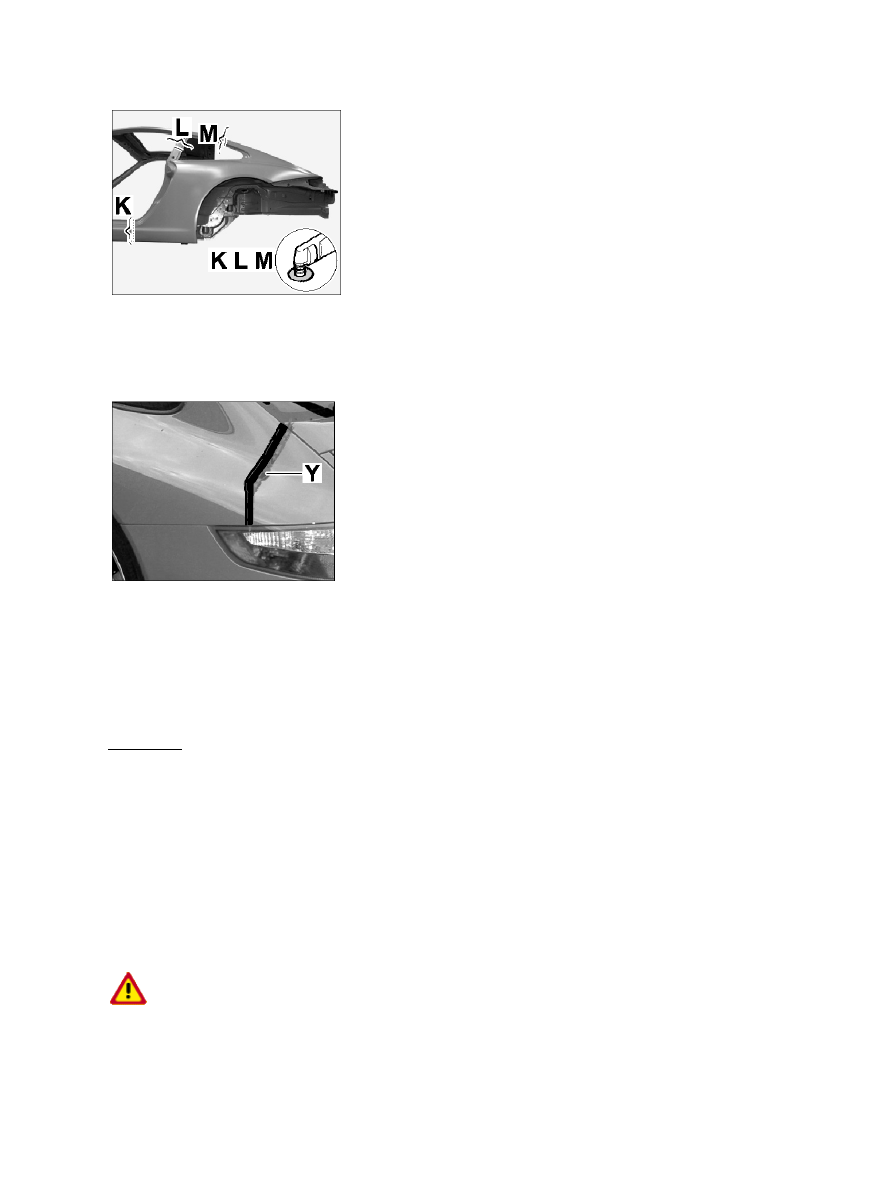

3. Cut through the side section at the marked joints K, L,

M

.

Removing expanded sealant

4. Remove expanded sealant

4.1. The side section is factory sealed with expanded sealant Y from the light housing to the rear centre

section connection. The expanded sealant will be destroyed when replacing the side section and must be

replaced.

Preparing connection areas of the body for installation of the

side section

Safety instructions for flying sparks during grinding and welding work

ATTENTION

Danger of explosion and fire from flying sparks during grinding and welding work!

Danger of injury and danger of damage to vehicle parts and other vehicles due to flying sparks

•

Diagnostic system: reading out fault memory and activating systems

Preparing connection areas of the body for installation of the side section

1697