Porshe 911 (997). Manual - part 358

Cleaning the welding areas

2. Cleaning the welding

areas

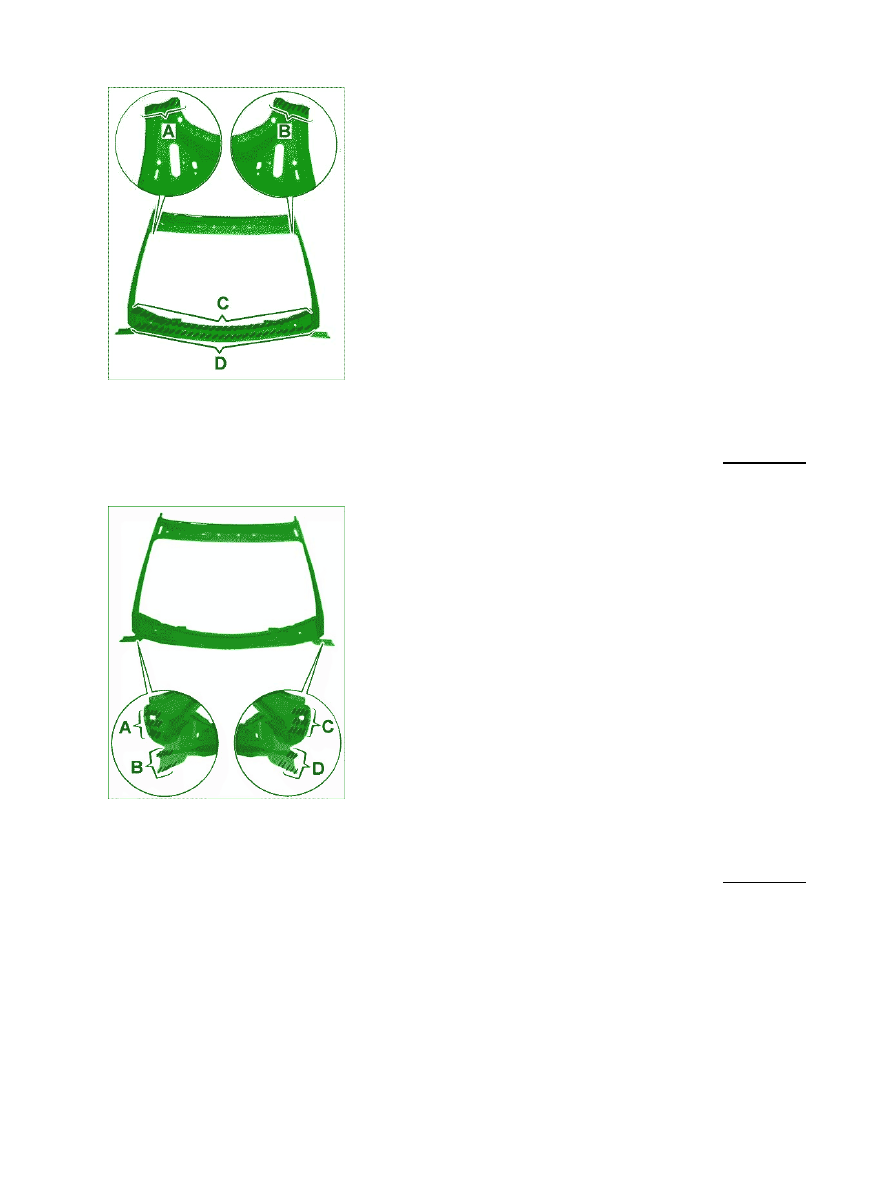

2.1. Grind both sides of the connecting flanges of the windscreen frame in the marked areas -A, B, C, D-

until bare using a rotary brush.

Cleaning the welding areas

3. Cleaning the welding

areas

3.1. Grind both sides of the connecting flanges of the windscreen frame in the marked areas -A, B, C, D-

until bare using a rotary brush.

Diagnostic system: reading out fault memory and activating systems

Fitting in windscreen frame and preparing for installation

1589