Porshe 911 (997). Manual - part 265

Wheel bolt

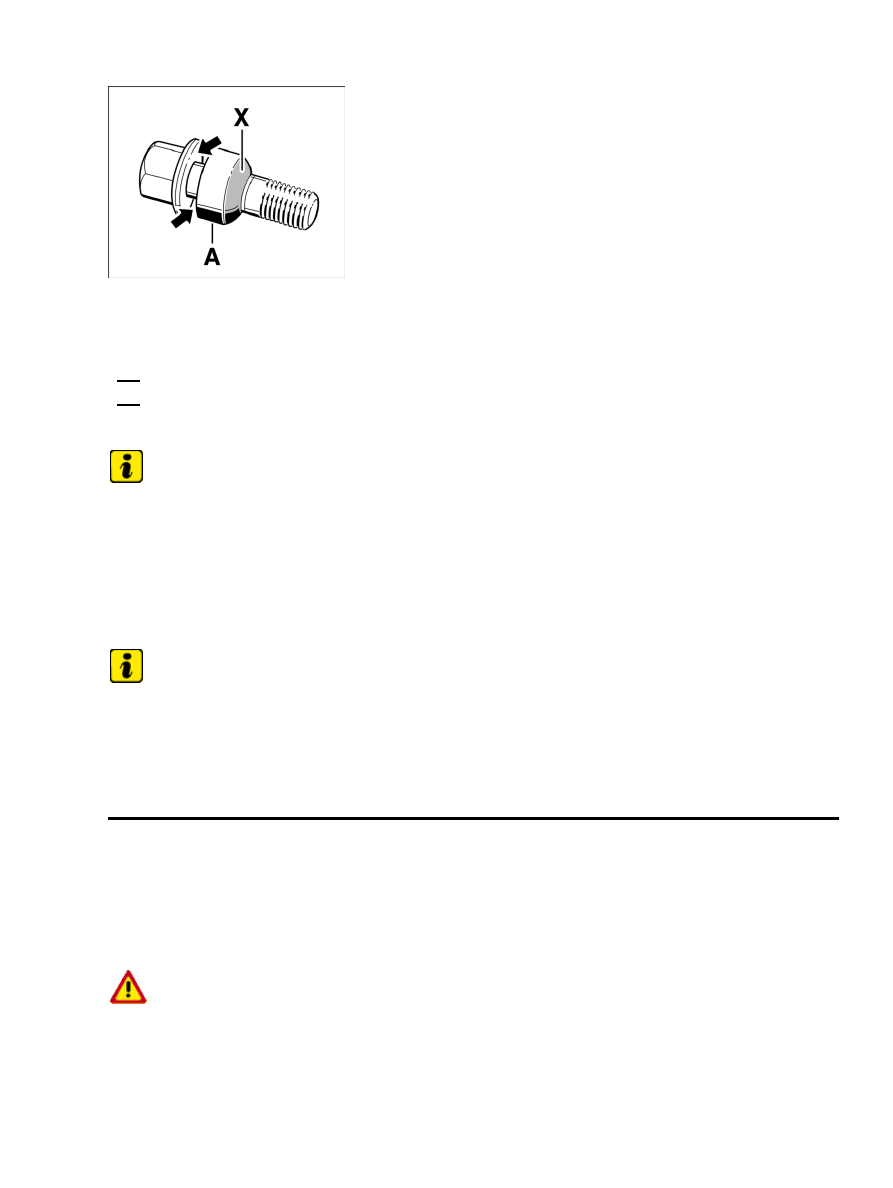

3. Always apply a thin coat of Optimoly TA (aluminium paste) on the thread of the wheel bolts, on the

shank and between the bolt head bearing surface and spherical cap ring (under the head) -arrows- .

Do not grease the spherical cap bearing surface -X- of the wheel bolts that face the wheel.

- Spherical cap ring (permanently connected with the wheel bolt)

- Spherical cap bearing surface facing the wheel (do not grease)

Note

Rework on wheel bolts is impermissible.

•

4. Always replace damaged wheel

bolts.

This damage includes mechanical damage to the thread, the spherical cap and damage resulting from seizure

of the bolt head bearing surface and spherical cap ring. It must be possible to rotate the spherical cap ring on

the bolt shank and to move it in axial direction.

Note

Always observe the specified tightening torque of 130 Nm (96 ftlb.).

•

5. Screw in wheel bolts by hand and then tighten evenly. Start at the top when

tightening.

997110, 997111, 997120, 997121, 997310, 997311, 997320, 997321, 997410, 997411, 997430, 997431,

997610, 997611, 997620, 997621

WARNUNG

Gefahr des Verlusts der Text-Bild-Zuordnung beim Ausdruck.

Aus technischen Gründen kann derzeit nicht ausgeschlossen werden, dass trotz

einwandfreier Darstellung auf dem Bildschirm beim Ausdruck der

•

Diagnostic system: reading out fault memory and activating systems

Installing wheel

1217