Porshe 911 (997). Manual - part 33

6

Thrust-bearing screw,

M9 x 127

14

Tightening torque

[Nm] (ftlb.)

7

Gear carrier half,

cylinder 1-3

1

8

Crankshaft

1

9

Thrust washer

2

Position correctly, oil

grooves always point

outwards

10

Gear carrier half,

cylinder 4-6

1

11

Connecting rods,

cylinder 4-6

3

Immediately join with the associated

connecting rod cap after removal

1. Fasten the special tool retaining device 9607 onto the workbench using two screw

clamps.

2. Mark connecting rod 4-6 in the installation position.

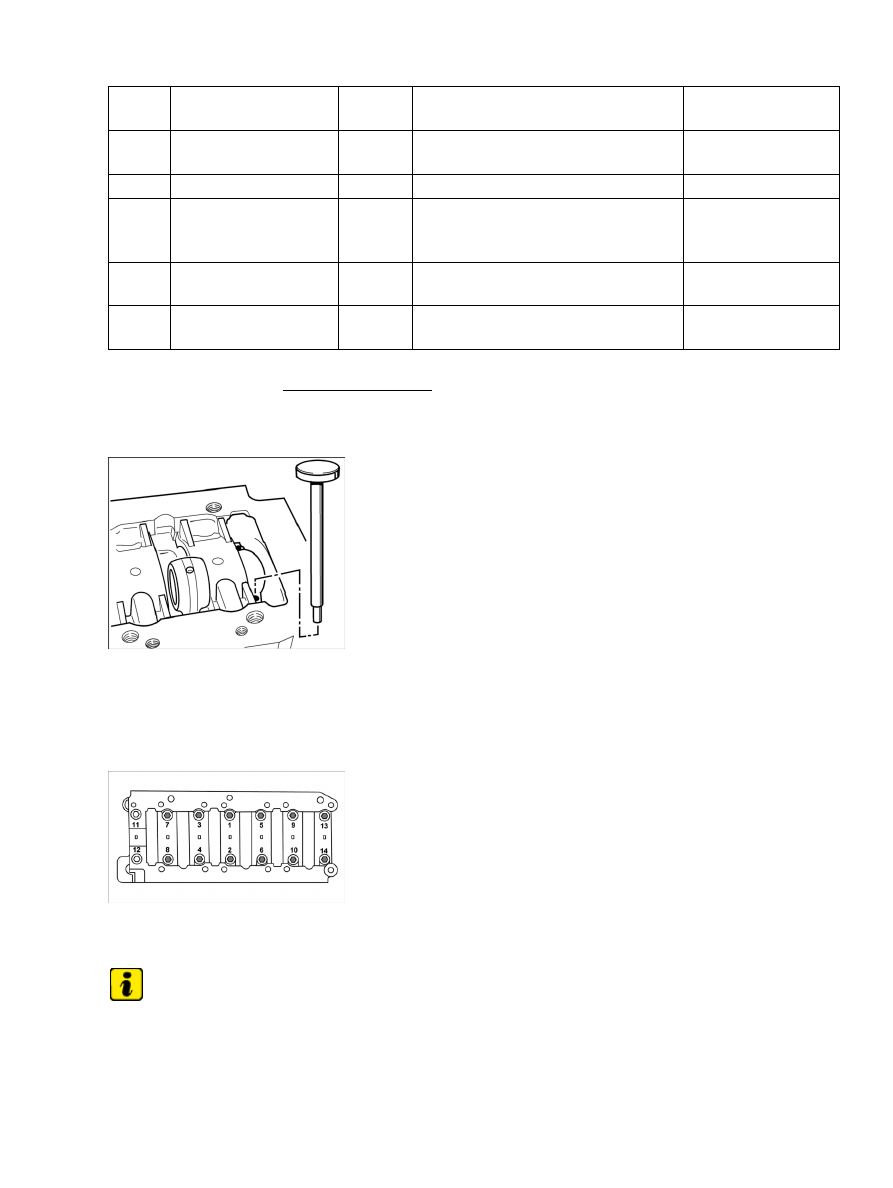

Plastic mandrel

3. Remove connecting rods on cylinder side 4-6 one after another. Loosen the two connecting rod

bolts on each connecting rod, remove connecting rod cap. Using a plastic mandrel (possibly an

in-house tool) push connecting rod down and out. Immediately after this, screw on loosely to

associated connecting rod cap. Place on a clean surface.

Gear carrier

4. Loosen 14 M9 x 127 screws for the gear carrier in the opposite order to the tightening sequence,

from the outside inwards, and unscrew them.

Note

Watch out for bearing shells and oil spray jets that may fall out

5. Remove gear carrier half 1-3, possibly tapping it gently with a plastic hammer.

Diagnostic system: reading out fault memory and activating systems

Removing crankshaft

289